In today’s competitive market, companies are increasingly turning to customized packaging solutions to meet the specific needs of their products and brands. Soft packaging, which is lightweight, flexible, and often used for food, beverages, cosmetics, and pharmaceuticals, has gained tremendous popularity. This guide will provide a comprehensive analysis of the soft packaging customization process, covering key steps, considerations, and best practices.

## Step 1: Define Your Requirements

The first step in the soft packaging customization process is to clearly define your packaging requirements. This includes:

-**Product Type**: Understand the nature of the product that will be packaged. Is it liquid, solid, powder, or a combination?

- **Dimensions**: Determine the size and shape of the packaging. Consider how the product will be dispensed and any space constraints.

- **Material Selection**: Choose suitable materials based on product compatibility, durability, and aesthetics. Common materials include plastic films, laminates, and bioplastics.

## Step 2: Market Research

Conducting thorough market research is vital. Analyze competitor packaging, industry trends, and consumer preferences. Understanding what resonates with your target market will guide the design process and help you differentiate your product.

## Step 3: Design Development

## Step 3: Design Development

After defining your requirements and conducting research, move on to the design phase. This involves:

- **Graphic Design**: Create eye-catching graphics and branding elements. Ensure that the design reflects your brand identity and appeals to your target audience.

- **Structural Design**: Develop the physical structure of the packaging. Consider how it will stand, seal, and open, as well as any additional features like windows or spouts.

## Step 4: Prototyping

Once the design is established, the next step is prototyping. This involves creating a physical sample of the packaging. Prototypes allow you to:

- Test the design for functionality and usability.

- Evaluate aesthetics and make necessary adjustments.

- Ensure that the packaging can effectively protect the product.

## Step 5: Testing

## Step 5: Testing

Testing is a critical phase in the customization process. Various tests should be conducted, including:

- **Durability Tests**: Assess the packaging’s ability to withstand handling, transportation, and storage.

- **Compatibility Tests**: Ensure the packaging material is suitable for the product it will contain, preventing interaction that could degrade the product.

- **Environmental Tests**: Evaluate performance under different environmental conditions, such as temperature and humidity.

## Step 6: Finalization and Approval

After testing and adjustments, finalize the packaging design. Present the final prototype to stakeholders for approval. This may involve gathering feedback from marketing, sales, and production teams to ensure alignment with business goals.

## Step 7: Production Setup

## Step 7: Production Setup

Once approved, prepare for mass production. This involves:

- **Supplier Selection**: Choose reliable suppliers who can provide the materials needed for your packaging.

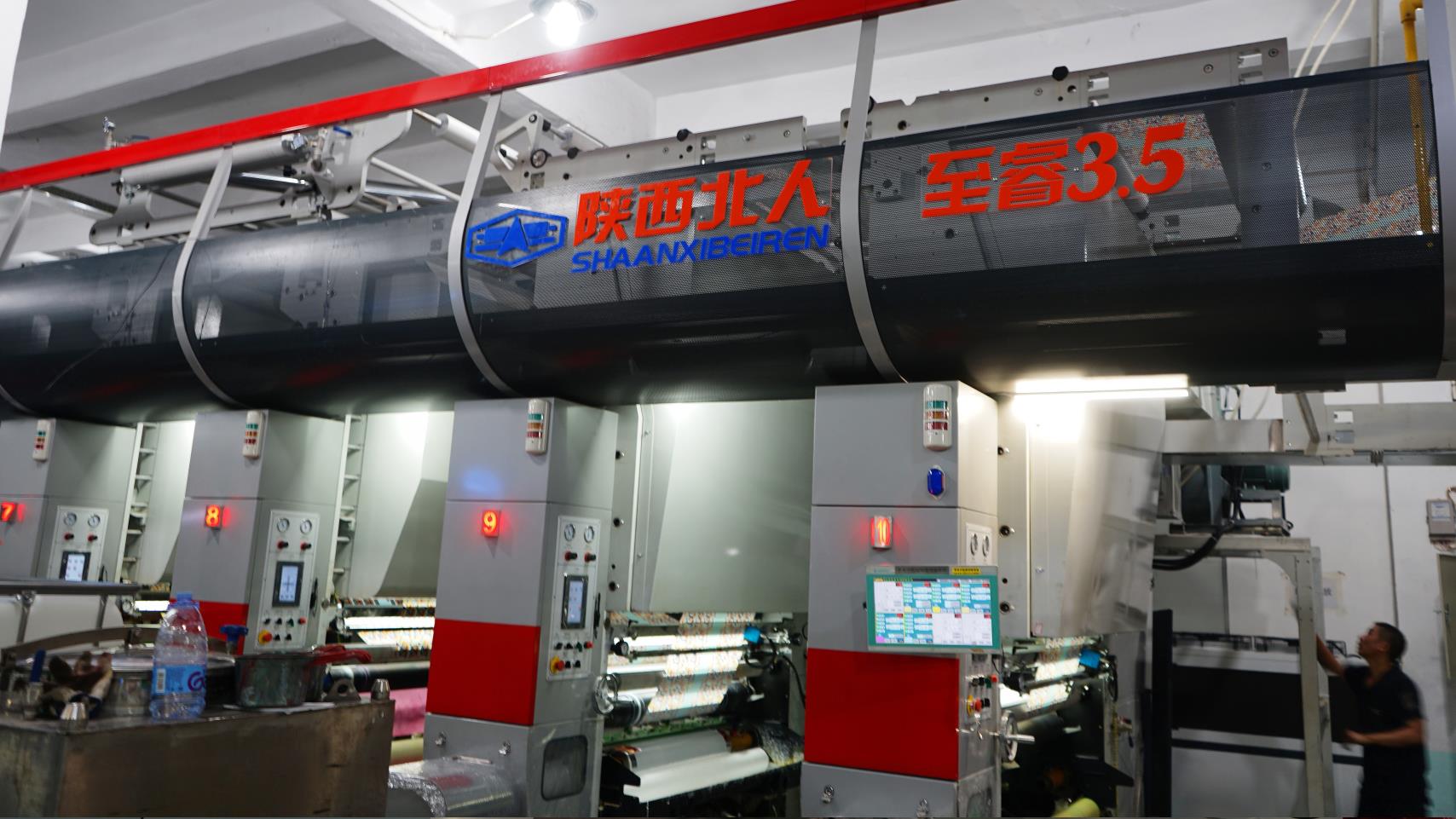

- **Machinery Setup**: Ensure that the production machinery is equipped to handle the custom design, including any printing or sealing functions.

## Step 8: Monitoring Production

During production, maintain oversight to ensure quality control. Regular checks can help identify issues early, preventing waste and ensuring that the final product matches the approved design.

## Step 9: Distribution and Feedback

## Step 9: Distribution and Feedback

After production, the packaging is ready for distribution. Monitor feedback from customers regarding the packaging’s usability, appeal, and overall performance. This feedback can inform future packaging iterations and enhancements.

## Best Practices for Soft Packaging Customization

## Best Practices for Soft Packaging Customization

1. **Sustainability**: Consider eco-friendly materials and designs that minimize environmental impact.

2. **Regulatory Compliance**: Ensure that the packaging meets all industry regulations and standards.

3. **Brand Consistency**: Maintain consistency in branding across all packaging materials to strengthen brand identity.

4. **Flexibility**: Be prepared to make adjustments based on market demands and consumer feedback.

## Conclusion

## Conclusion

The soft packaging customization process is a multifaceted endeavor that requires careful planning and execution. By following these steps and best practices, businesses can create packaging solutions that not only protect their products but also enhance brand visibility and customer satisfaction. As consumer preferences evolve, staying proactive in your packaging strategy will ensure long-term success in a competitive marketplace.

Post time: Feb-14-2025