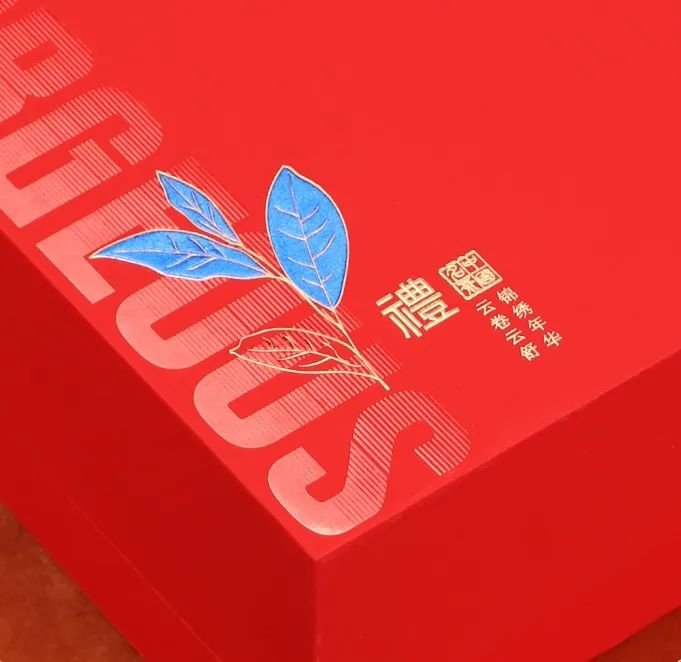

Isitampu esishushu siyindlela ebalulekileyo yentsimbi yomphezulu wokuhombisa, nangona ushicilelo lwe-inki yegolide kunye nesilivere kunye nesitampu esishushu sinesiphumo sokuhombisa sesinyithi esikhazimlayo, kodwa ukufumana impembelelo ebonakalayo eyomeleleyo, okanye ngenkqubo yokushicilela eshushu ukufikelela.

Ngenxa yokuqhubekeka kokwenziwa kwezixhobo zokutampu ezishushu kunye nezixhobo ezixhasayo, ziphucula ukubonakaliswa kweendlela ezishushu zokubetha, ngoku inkqubo yokutampa eshushu ineentlobo ezisi-7:

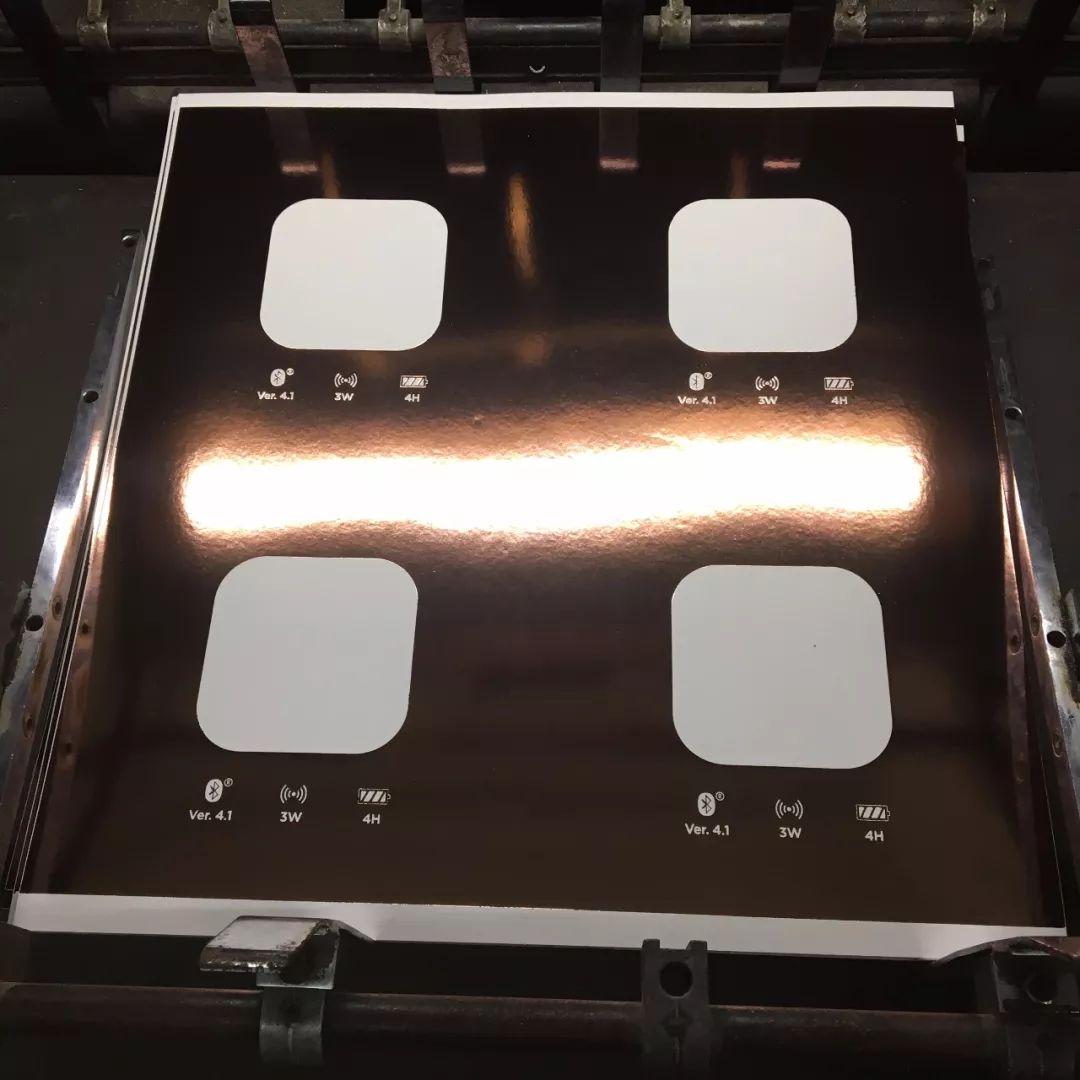

Eyona nto ixhaphakileyo isitampu esishushu, sishiya umhlophe ujikeleze ukuqaqambisa umzimba oshushu. Xa kuthelekiswa nezinye isitampu, inkqubo yokuvelisa ilula, kwaye ukuba inani alikho likhulu, i-zinc plate stamping ingasetyenziswa.

Isitampu esisicaba, sibhekisa kumphezulu wedatum yimbonakalo emcaba, isitampu kwisixhobo sokusetyenzwa esisicaba okanye inxalenye yendiza yomsebenzi.

Olu hlobo lwesitampu, lunokuba yimizobo yeconvex, isitampu kumphezulu osicaba; inokuba yipleyiti ye-silicone ecaba, ukunyathela kwimizobo ephakanyisiweyo.

2: ibala elichasene nomhlophe isitampu

Okuchaseneyo kwindlela yokuvelisa i-ayini ye-ayina, inxalenye yomxholo we-white, kunye nenxalenye yangasemva ye-stamping, i-stamping ubungakanani bendawo ngokweemfuno zoyilo lwemveliso, ukuba indawo ye-stamping inkulu, kufuneka ithathelwe ingqalelo ukusebenza kwayo kokunamathela ukuhlangabezana neemfuno zenkqubo.

Ngokweemfuno zomfanekiso, ukwenzela ukwenza isitampu kunye nokushicilela inxalenye yokudibanisa okuhlakaniphile, okokuqala ukuprinta ngaphambi kokushicilela. Inkqubo yokuvelisa iphezulu yokubhalisa kwaye idinga ulungelelwaniso oluchanekileyo ukuze ufumane umphumo ogqibeleleyo.

4: isitampu sefoyile yerefractive

Imveliso yoguqulelo lwesitampu, owona mfanekiso uphambili kunye nemizobo engasemva enobunzima obahlukeneyo okanye ukuya kumgca njengesahlulelo, senza isiphumo sokuphinda sibonakale, sigxininisa ingqiqo yobugcisa bomgca wegrafiki, ngokuqhelekileyo kusetyenziswa uguqulelo olukroliweyo lwelaser.

Kuloo ndawo umzobo ngokuphindaphindiweyo stamping ngaphezu kabini, kufuneka ukuya ngokusebenzisa inkqubo ezininzi, kodwa kwakhona kufuneka ingqalelo iintlobo ezimbini ngefoyile yegolide iyahambelana, ukuze kuthintelwe isenzeko of adhesion ayiqini.

Uqheliselo olufana nolwelo lokunyathela emva koko lufake i-embossing, kodwa i-embossing stamping inika ingqwalasela engakumbi kwi-texture ye-stamping kunokuba i-embossing isiphumo, ngokuqhelekileyo kusetyenziswa uguqulelo lwe-embossing stamping, ukuphakama kweemfuno eziphakanyisiweyo kufuneka zibe kuxinzelelo lwe-foil surface yegolide inokuthwala uluhlu.

Emva kokuba imveliso yokucokisa itekhnoloji yokucofa ikhombisa isiqabu-efana nesiphumo sepateni enomacala amathathu, ngoko ke ukusetyenziswa koshicilelo lokuqala kunye nendlela yenkqubo yokunyathela, kwaye ngenxa yokuchaneka kwayo okuphezulu kunye neemfuno ezikumgangatho ophezulu, zilungele ngakumbi ukusetyenziswa kwetekhnoloji yokushicilela eshushu.

Njengoko unokucinga, abaqulunqi kufuneka baqwalasele ngononophelo ukuthungwa, ubunzima, i-foil yegolide kunye ne-inki xa ukhetha iphepha okanye ezinye izinto zokuthwala zenkqubo ye-foil ene-dimensional-dimensional stamping, kunye nokulungelelaniswa kwecala langaphambili nasemva kubalulekile.

Ngexesha elifanayo, ubukhulu bephepha buya kunciphisa umgangatho kunye nomphumo wemveliso yakho egqityiweyo ngexesha lenkqubo. Umzekelo, iphepha elibhityileyo kakhulu okanye elincinci kakhulu lingakhokelela kwiingxaki zokuphuma kwephepha.

7: isiphumo esikhethekileyo ukutyumba isitampu

Ngokweemfuno zokuyila, ukuveliswa kweempembelelo ezikhethekileyo ze-textile stamping, ukugqamisa isiphumo esikhethekileyo somatshini.

Kusetyenziso olusebenzayo lwenkqubo yesitampu eshushu, ukhetho lwepleyiti yesitampu yentsimbi, iphepha lokutampa elishushu, iphepha, indlela yokubonakalisa isitampu eshushu echaphazela ngokuthe ngqo isiphumo sokugqibela sesitampu esishushu.

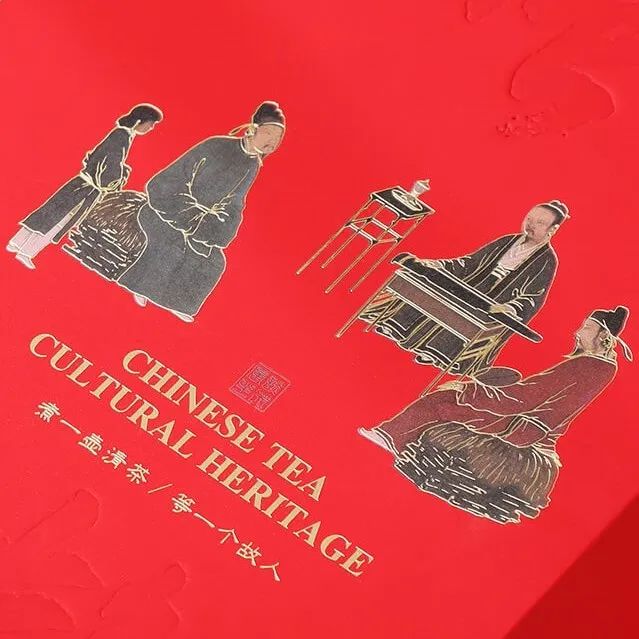

Isitampu esishushu kule mihla sisetyenziswa ngokubanzi kwiindawo ezahlukeneyo zokuprinta kunye nokupakisha. Ikwabubuchule bokushicilela kuphela obuvelisa isiphumo sesinyithi esimenyezelayo, esingadyobhekiyo ephepheni, kwiplastiki, kwikhadibhodi, nakwezinye iindawo eziprintiweyo.

Ixesha lokuposa: Feb-10-2023